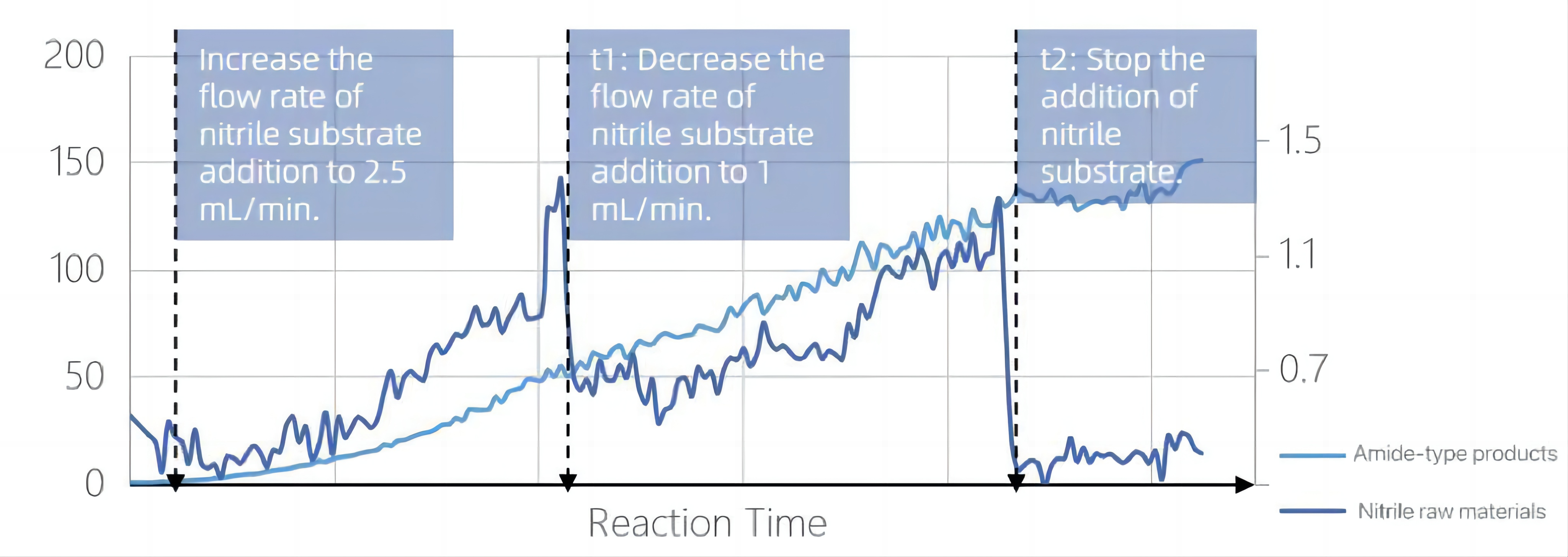

Online monitoring ensures that the substrate content is below the threshold, ensuring biological enzyme activity throughout the process, and maximizing the hydrolysis reaction rate

Amide compounds are important organic synthesis intermediates and chemicals and are widely used in medicine, pesticides, food, environmental protection, oil production and other fields. The hydrolysis reaction of nitrile group into amide group is one of the important methods for preparing amide compounds in industry.

A biocatalyst is used in the green synthesis process of a certain amide compound, and its activity is greatly affected by the concentration of substrate and product in the system. If the substrate concentration is too high, the catalyst will be easily deactivated, making it impossible to continue the synthesis reaction; if the product concentration is too high, it will also lead to accumulation of substrate and low synthesis efficiency. In order to ensure the optimal activity of biological enzyme catalysts in synthesis reactions, effective technical means are needed to monitor and feedback adjust the concentrations of nitrile substrates and amide products in real time during the reaction process.

At present, methods such as sampling at fixed intervals and performing gas chromatography-mass spectrometry after sample pre-treatment are often used to detect the substrate and product content in the reaction system. Offline detection results lag, the current reaction status cannot be known in real time, and it is difficult to perform feedback control and adjustment of substrate content, and the best feeding opportunity may be missed. Online spectral analysis technology has the advantages of fast detection speed and no need for sample pretreatment. It can realize fast, real-time, in-situ and intelligent analysis of the reaction system, and has exceptional advantages in the green synthesis of amide compounds.

The picture above shows the online monitoring of the process of preparing acrylamide through the bioenzymatic reaction of a certain nitrile compound. From 0 to t1 after the reaction starts, the feeding rate of nitrile raw materials is relatively large, and the accumulation rate of both substrate and product is relatively fast. At t1, the substrate content is close to the upper limit of the threshold. At this time, the production personnel reduce the feeding rate of raw materials to keep the substrate concentration in the reaction system within a controllable range, and the product can still accumulate quickly. Finally, when the reaction proceeds to time t2, the product content accumulates to the target level, and the production staff stops adding nitrile raw materials. After that, the substrate level approaches zero and the product content also tends to be stable. During the entire continuous production process, online monitoring ensures that the biological enzyme catalytic reaction proceeds efficiently.

In large-scale synthesis, online monitoring technology is particularly important. Real-time knowledge of substrate and product concentrations can help feedback to adjust the substrate content within a reasonable range. During the reaction process, it can maximize the activity of the biological enzyme catalyst, improve the efficiency of the synthesis reaction, and help control the process parameters in the optimal state. Extend the service life of biological enzyme catalysts and maximize benefits.

Post time: Jan-23-2024