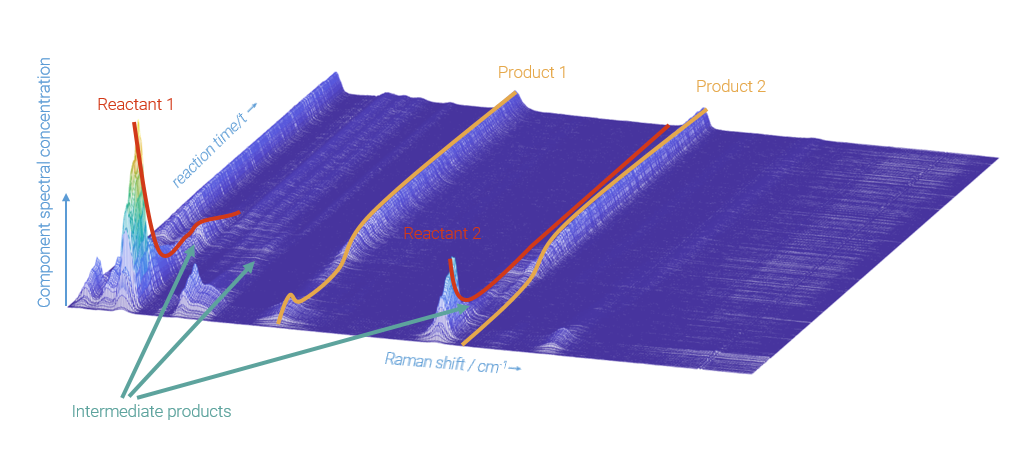

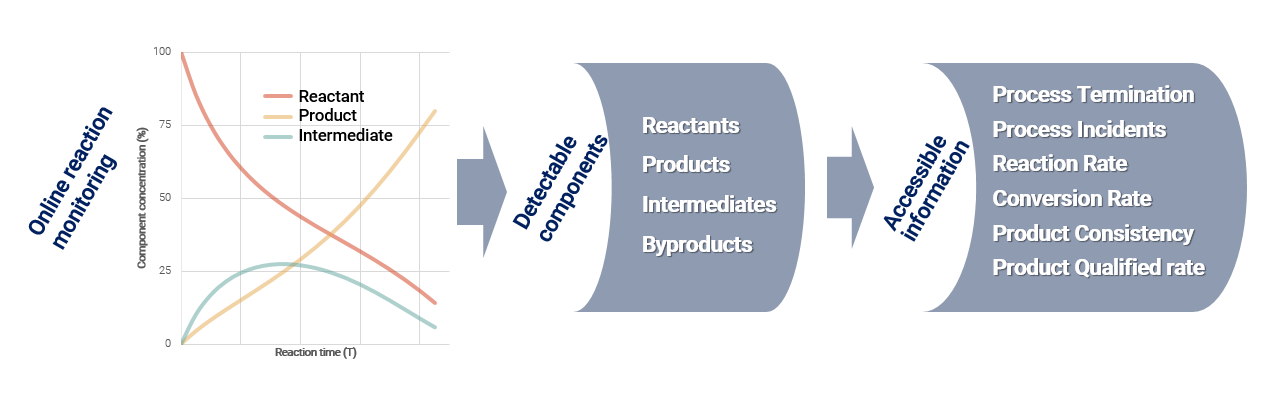

In-situ, real-time, continuous on-line analysis of chemical reactions and biological processes for the study of reaction mechanisms, process development and optimization, and for the realization of precise process control.

●Can withstand extreme reaction conditions such as strong acid, strong alkali, strong corrosiveness, high temperature, and high pressure.

●Real-time response in seconds, no need to wait, providing analysis results promptly.

●No sampling or sample processing required, in-situ monitoring without interference to the reaction system.

●Continuous monitoring to quickly determine the reaction endpoint and alert for any anomalies.

Chemical/pharmaceutical/materials process development and production requires quantitative analysis of components. Usually, offline laboratory analysis techniques are used, where samples are taken to the laboratory and instruments such as chromatography, mass spectrometry, and nuclear magnetic resonance spectroscopy are used to give information on the content of each component. The long detection time and low sampling frequency cannot meet many real-time monitoring needs.

JINSP provides online monitoring solutions for chemical, pharmaceutical, and material process research and production. It enables in-situ, real-time, continuous, and rapid online monitoring of the content of each components in reactions.

1. Analysis of Chemical Reactions/Biological Processes under extreme conditions

Under conditions of strong acids, strong alkalis, high temperature, high pressure, strong corrosion, and toxicity, conventional instrument analysis methods may face challenges in sampling or cannot withstand active samples. However, online monitoring optical probes, specially designed to adapt to extreme reaction environments, stand out as the sole solution.

Typical Users: Researchers involved in extreme chemical reactions at new material companies, chemical enterprises, and research institutes.

2. Research and Analysis on Intermediate Reaction Components/Unstabl

Short-lived and unstable reaction intermediates undergo rapid post-sampling changes, making offline detection inadequate for such components. In contrast, real-time, in-situ monitoring through online analysis has no impact on the reaction system and can effectively capture changes in intermediates and unstable components.

Typical Users: Experts and scholars from universities and research institutes interested in the study of reaction intermediates.

3. Time-Critical Research and Development in Chemical/Bio-processes

In research and development with tight timelines, emphasizing time costs in chemical and bioprocess development, online monitoring provides real-time and continuous data results. It promptly reveals reaction mechanisms, and big data assists R&D personnel in understanding the reaction process, significantly accelerating the development cycle.Traditional offline detection provides limited information with delayed results, leading to lower R&D efficiency.

Typical Users: Process development professionals in pharmaceutical and biopharmaceutical companies; R&D personnel in new materials and chemical industries.

4. Timely Intervention in Chemical Reactions/Biological Processes with Reaction Anomalies or Endpoints

In chemical reactions and biological processes such as biofermentation and enzyme-catalyzed reactions, the activity of cells and enzymes is susceptible to the influence of relevant components in the system. Therefore, real-time monitoring of abnormal concentrations of these components and timely intervention are crucial for maintaining efficient reactions. Online monitoring provides real-time information about the components, while offline detection, due to delayed results and limited sampling frequency, may miss the intervention time window, leading to reaction anomalies. Typical Users: Research and production personnel in biofermentation companies, pharmaceutical/chemical companies involved in enzyme-catalyzed reactions, and enterprises engaged in the research and synthesis of peptides and protein drugs.

5. Product quality/Consistency Control in Large-Scale Production

In the large-scale production of chemical and biological processes, ensuring the consistency of product quality requires batch-by-batch or real-time analysis and testing of reaction products. Online monitoring technology, with its advantages of speed and continuity, can automate quality control for 100% of batch products. In contrast, offline detection technology, due to its complex processes and delayed results, often relies on sampling, posing quality risks for products not sampled.

Typical Users: Process production personnel in pharmaceutical and biopharmaceutical companies; production personnel in new materials and chemical companies.

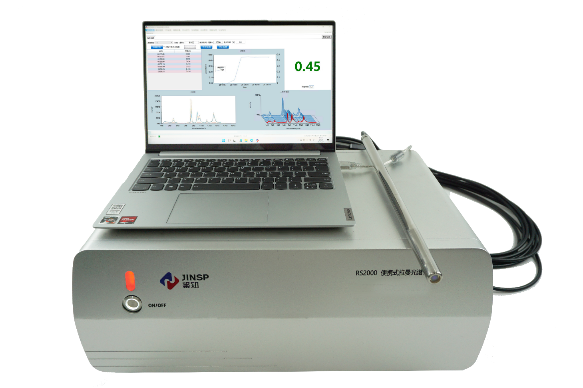

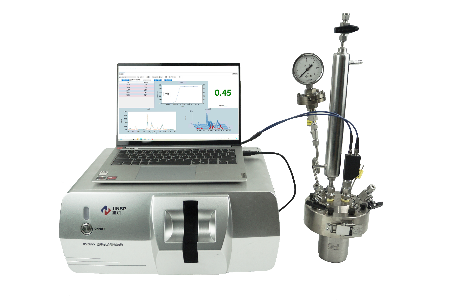

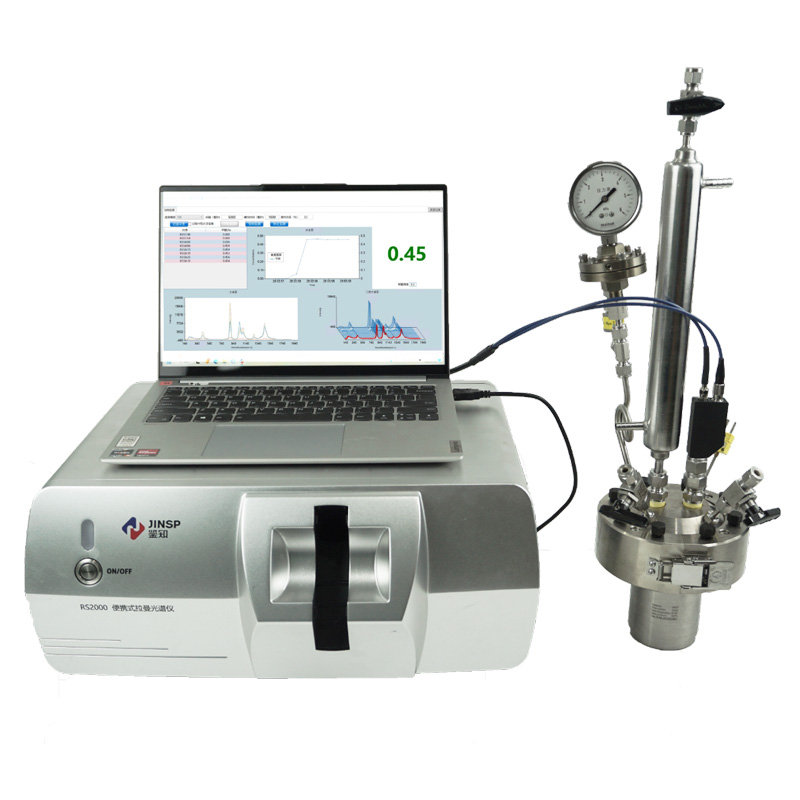

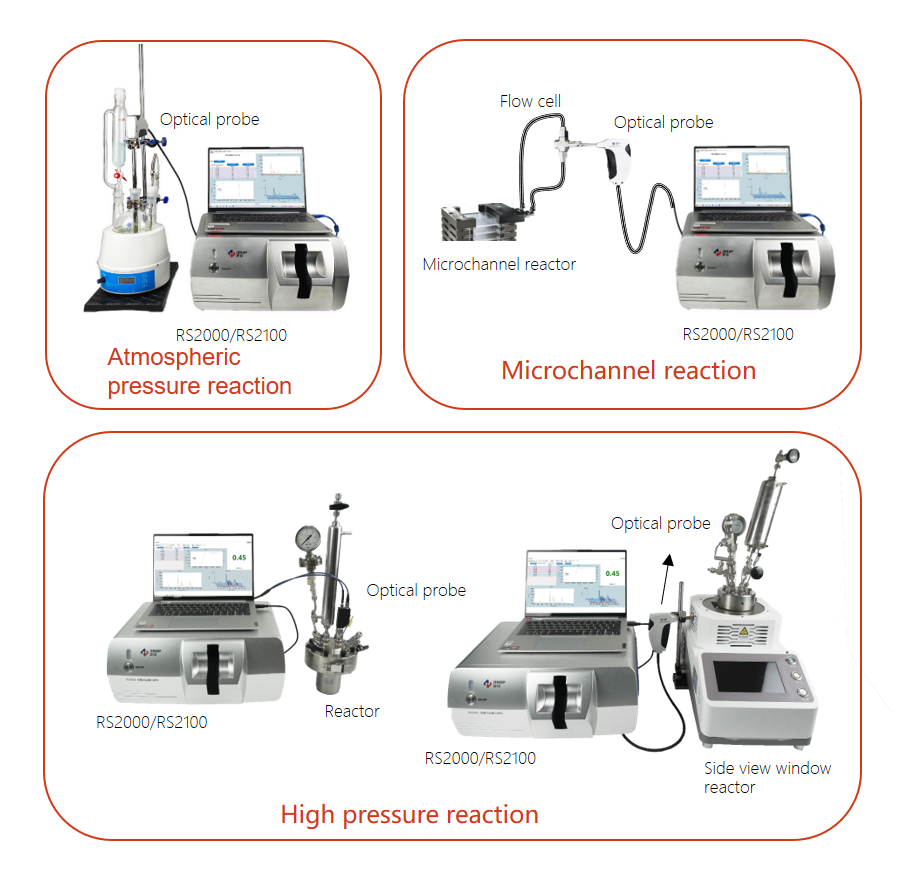

RS2000/RS2100 has three usage modes in the laboratory, and each mode requires different accessories.

1. The first mode uses an immersed long probe that goes deep down to the liquid level of the reaction system to monitor each reaction component. Depending on the reaction vessel, reaction conditions, and system, different specifications of probes are configured.

2. The second mode involves using a flow cell to connect a bypass probe for online monitoring, which is suitable for reactors like microchannel reactors. Various probes are configured based on the specific reaction vessel and conditions.

3. The third mode utilizes an optical probe directly aligned with the side window of the reaction vessel for reaction monitoring.

Li-ion battery industry

News - Research on the synthesis process of bis(fluorosulfonyl)amide (jinsptech.com)

Biopharmaceutical industry

News - Drug crystal form research and consistency evaluation (jinsptech.com)

News - Quality Control in Biofermentation Engineering (jinsptech.com)

Fine chemical industry

News - Research on the process of producing furfuryl alcohol by hydrogenation reaction of furfural (jinsptech.com)

News - Process control of bioenzyme catalytic reactions of nitrile compounds (jinsptech.com)

News - A certain ultra-low temperature nitrification reaction (jinsptech.com)

News - Research on o-xylene nitration reaction process (jinsptech.com)