Online monitoring of glucose content for real-time feeding to ensure the smooth completion of the fermentation process.

Biofermentation engineering is one of the important components of modern biopharmaceutical engineering, obtaining the desired biochemical products through the growth process of microorganisms. The microbial growth process includes four stages: adaptation phase, log phase, stationary phase, and death phase. During the stationary phase, a large amount of metabolic products accumulate. This is also the period when products are harvested in most reactions. Once this phase is exceeded and the death phase is entered, both the activity of the microbial cells and the purity of the products will be greatly affected. Due to the complexity of biological reactions, the repeatability of the fermentation process is poor, and quality control is challenging. As the process scales up from the laboratory to pilot scale, and from pilot scale to large-scale production, abnormalities in reactions can easily occur. Ensuring that the fermentation reaction is maintained in the stationary phase for an extended period is the most concerning issue when scaling up fermentation engineering.

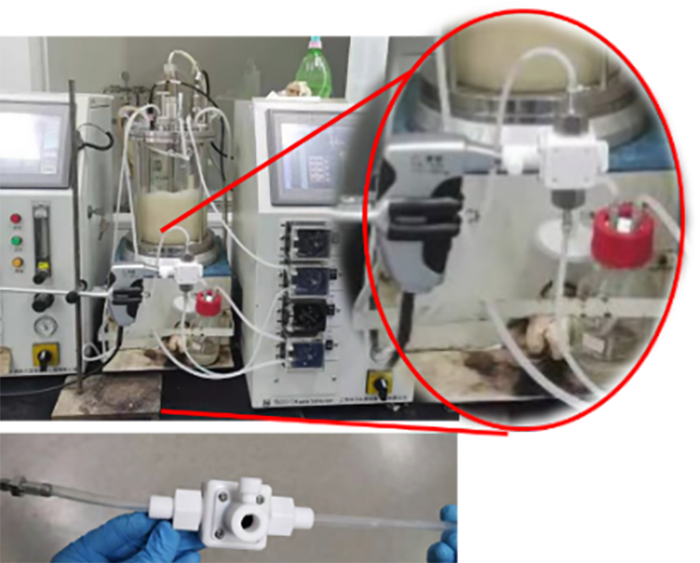

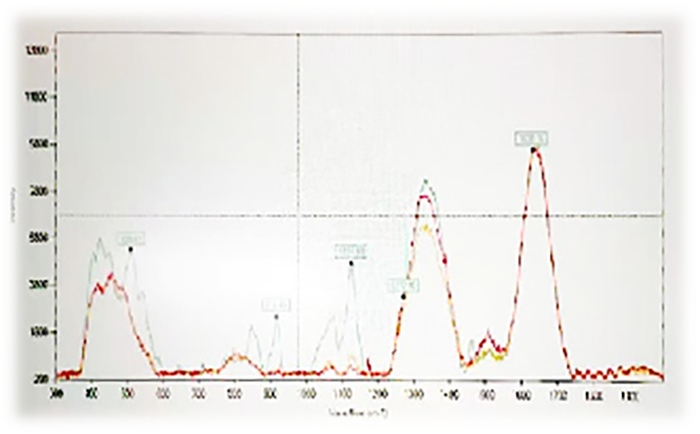

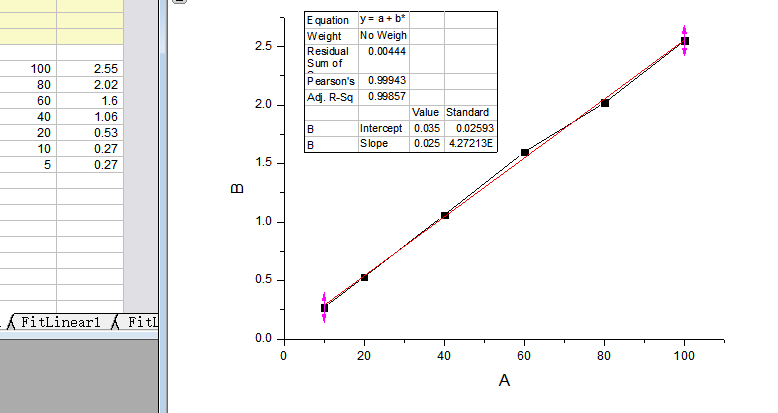

To ensure that the microbial strain remains in a vigorous and stable growth phase during fermentation, it is crucial to maintain the content of necessary energy metabolites such as glucose. Using online spectroscopy to monitor the glucose content in the fermentation broth in real-time is a suitable technical approach for controlling the biofermentation process: taking the changes in glucose concentration as the criteria for supplementation and determining the state of the microbial strain. When the content falls below a set threshold, supplementation can be promptly carried out based on monitoring results, significantly enhancing the quality and efficiency of biofermentation. As shown in the diagram below, a side branch is drawn from a small fermentation tank. The spectroscopy probe obtains real-time fermentation liquid signals through a circulation pool, ultimately allowing detection of glucose concentrations in the fermentation liquid down to as low as 3‰.

On the other hand, if offline sampling of the fermentation broth and laboratory testing are used for process control, the delayed detection results may miss the optimal timing for supplementation. Furthermore, the sampling process may affect the fermentation system, such as contamination by foreign bacteria.

Post time: Dec-07-2023